One great way to get an idea of relative difficulties is by looking at the description of the wood parts-only kits. As a first approximation, the kit with greater number of parts will take longer to complete. Here's the Skerry:

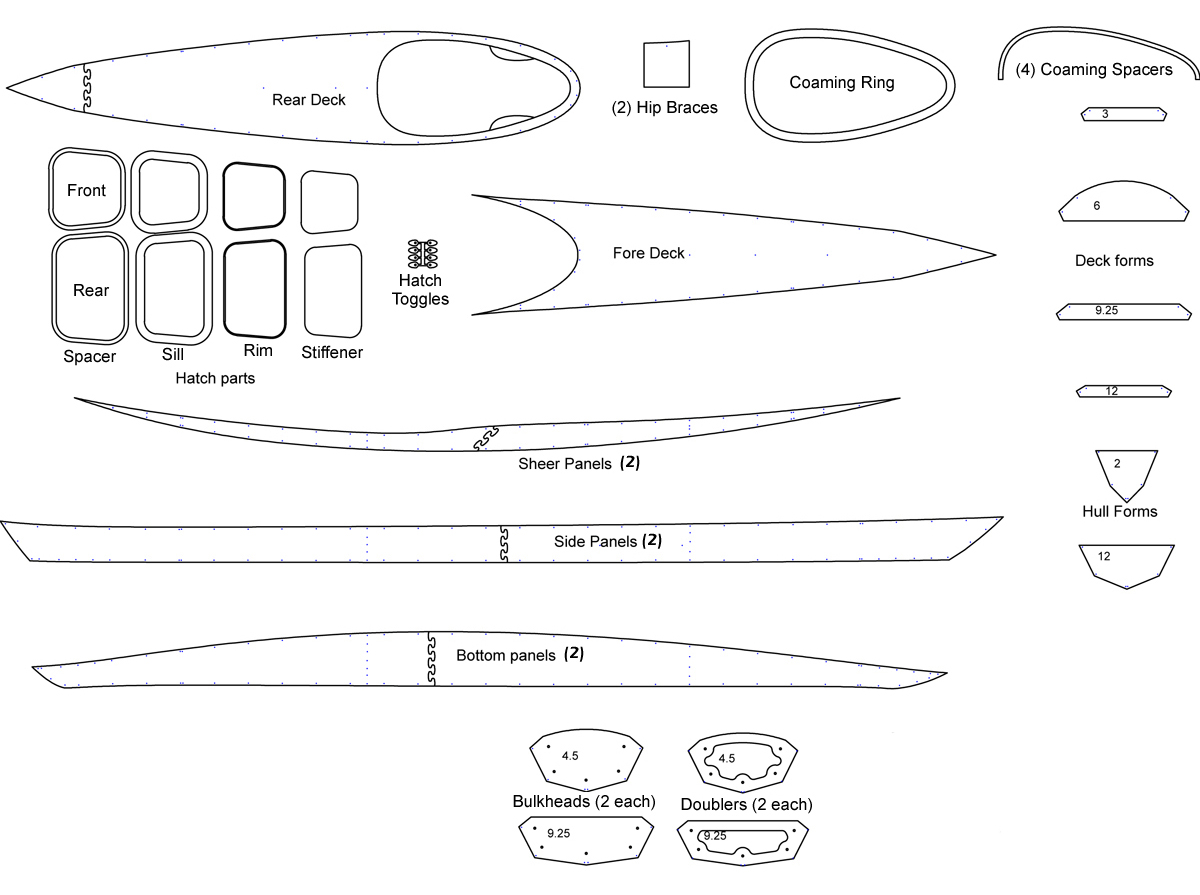

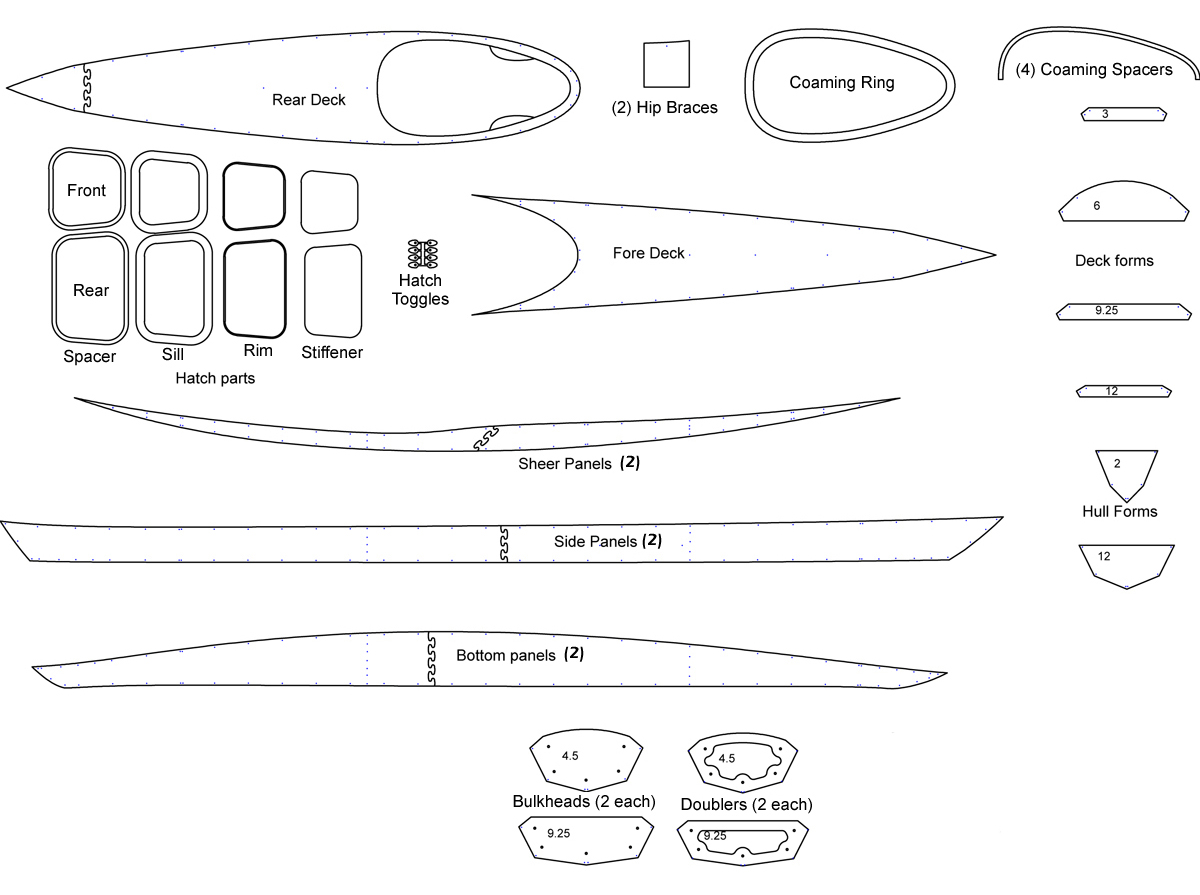

Here's the Sectional Shearwater Sport (note that some of the parts are duplicated so the count is closer to the Skerry than it may look at first):

You can get a more nuanced idea by examing the types of wood pieces. For example, the Skerry has one more side panel set and they're all rabbetted. The latter is not a big deal for fabrication if you buy the kit, but could make a noticeable difference if you're building from plans. The SSS panels will need to be beveled.

There are 2 more bottom pieces for the SSS and the 2 halves need to be stitched together, unlike for the Skerry.

The Shearwater Sport deck construction with the 15 deck, coaming and hatch cover pieces is more complex than the 5 seats and breasthooks on the Skerry, but not terribly so.

The bulkheads and doublers on the SSS pretty much match up the complexity of the frames on the Skerry.

Parts unique to the Skerry that have no counterparts on the SSS are the inwales and ouwales and the sailing parts (daggerboard trunk and skeg/wormshoe).

Of course, the Sectional Shearwater Sport has that pesky "sectional" thing which involves double bulkheads with corrugated cardboard sandwiched between them and the appointment with Dr. Saw, plus installing the hardware to hold it all together on the water. This is balanced by the greater weight of the Skerry which makes handling it toward the end of construction a more difficult process than a nice lightweight kayak. For example, turning the Skerry over to sand/paint the bottom is definitely more work than flipping the SSS, even in one piece.

Over all, I'd rate the 2 boats as about equivalent in effort. I'd rather rate the sailing components as a whole separate project because once the Skerry hull is done you have a boat that's roughly equivalant to the SSS in that you can get in and move it through the water with muscle power.

As far as the finishing effort, you have the CLC class to partially thank for that. That's because if you build neatly enough to make finish work easy it's a slow build. If you build quickly, it tends to be messy, at least on the first couple of boats, and needs a lot of sanding. Without any criticism, CLC balances this toward the fast build. They have to do this because the classes are typically under a week long, sometimes with a new one starting prep the next day. Sanding, on the other hand can be done by the student at home.

As builders gain experience, they learn how to combine speed with neatness. Building at home they can also take an extra day to smooth fillets so they need no sanding or to apply epoxy such that there are no drips, all without disrupting the class schedule.

For example, my first fully finished S&G boat took a solid month to prep and paint after construction was complete. My latest took 3 days. Even allowing for the difference in sizes, I was still at least 5 time faster.

So to bring this to a close, I'd agree with Howard that the Shearwater is less work than a Skerry, but I'd add not by much. However, your skills and efficiency have increased to the point that it will feel like less work than it actually will be and will go faster. And if you build it at home where you'll have the time to control your build for neatness, the finish work will be a lot less than on the Skerry.

Have fun,

Laszlo