To expand a bit on Steve’s reply:

TLDR:

- You can pre-glass if the curve is gentle enough

- You can test the curve for suitability for pre-glassing

- Pre-glassed panels stitched before the epoxy fully cures will be more flexible

- Panels glassed only on one side (typically inside) will be more flexible

- If this is to avoid sanding in confined spaces, there’s other ways than pre-glassing:

- Pre-saturate the glass

- Blot the glass

- Use many thin coats instead of several thick ones

- Fill the weave with epoxy/phenolic microballoon mix instead of unthickened epoxy when painting

- Deviate from the manual at your own risk

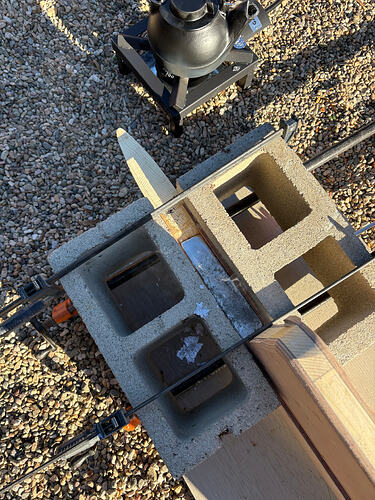

If the curve is gentle enough, glassing before assembly is no problem. The trick is figuring out if it’s gentle enough. One way to do this is to actually bend the wood to the final shape and see how much effort it takes. Since Steve was able to pre-glass the cabin top, that’s a known calibration point. If the bare wood takes the same or less effort to bend than the cabin top, it’s a candidate for pre-glassing.

Looking at the construction gallery, it looks as if the bow section, just as Steve mentioned is the real trouble spot, but the rest looks as if it’ll probably be OK to pre-glass.

You can also work a little differently to accommodate pre-glassing. For one thing, epoxy takes a while to fully cure. Depending on the temperatures in your work area, it could take days to weeks before it’s fully cured. In most cases, for the first 2 or three days it’s got reasonable flexibility. So you could glass a piece while it’s flat, then as soon as it’s cured to where it’s no longer tacky to the touch, bend it into place and stitch it.

Be aware that doing this requires more thought and preparation (and some skill) than the sequence in the manual. It will not necessarily save you calendar and clock time; it may take more. It just changes the kind of work that you have to do. It also puts some serious timing constraints on the assembly process. You have to stitch panels into place when they’re ready, not when you’re ready.

Another possibility is to pre-glass only the interiors. Access to the exterior sides of the pieces is pretty good throughout the build, it’s only the interior that needs contortions. Leaving the exterior unglassed while pre-glassing the inside helps reduce the bending/stiffness problems. With no glass on the outside, there’s no additional tension to resist bending from the outside. The inside is being compressed, which uncured glass/epoxy can’t resist as strongly as tension.

So pre-glassing is manageable, but keep in mind that it is more complex and has a higher chance of something going wrong than the sequence in the manual. Anyone deviating from the manual should have enough experience to know what they’re doing.

But, if your main goal is avoiding sanding, that’s a lot easier to do. First, keep in mind that most of the difficult interior surfaces will be invisible, covered by the cockpit and cabin soles. Personally, in those cases I see no reason to sand them, or to even fill the weave or paint them.

Second, the main reason to sand is to remove the globs and drips caused by applying too much epoxy. That can be handled without sanding in at least three ways - pre-saturate the glass outside the boat, apply many thin coats instead of several thick ones and use paper towels to blot the excess.

Pre-saturation is done on a large table covered in polyethylene sheeting. Spread out the glass, mix up the epoxy and wet the glass out. Spread the epoxy thoroughly and evenly, using only enough to thoroughly saturate the glass. Roll the glass up, move it into the boat onto the desired surface and unroll it, smoothing it into place with a gloved hand. This is an extremely messy process needing a significantly larger space for the table and possibly a helper. When mastered, though, it gives you a nearly perfect wetting out with little or no sanding. Again, it only changes the type of work you’re doing, not eliminating any.

The paper towel method is one that I adapted from a model airplane builder who posted here some 20 years or so ago. He (I’ve lost the name so I can’t give him full credit) suggested using toilet paper as a blotter. Once you’ve wet out the glass, just unroll the paper over the glass, let is sit for 60 seconds or so while it blots up the excess (you’ll see it change color as it does this) and then remove and discard the paper. I changed the method to use paper towels, to gently pat them into place and then, once they’re removed, to tip the surface with a dry foam brush to remove bubbles and any imprint if the paper had an embossed pattern. The result is an essentially perfect matte surface that needs no sanding at all, ready for the weave to be filled. This is similar to the result you get with Peel-Ply, except a lot cheaper and without the compound bending problems. The downside is the enormous amount of trash that this method generates. As long as you let the soaked paper towels fully cure, they won’t be hazardous waste, but there will be a lot. On the other hand there won’t be clouds of microplastic dust, sanding disks, noise and it uses no electricity.

Lots of thin coats instead of several thick ones works because epoxy that isn’t there can’t drip. It does take more time, though.

Another way to avoid sanding effort is to fill the weave with epoxy/phenolic microballoon mix under paint, rather than with unthickened epoxy. The mix is much easier to sand. Because of the color it can’t be used under varnished finishes.

So this post has gone on long enough, hope it helps,

Laszlo