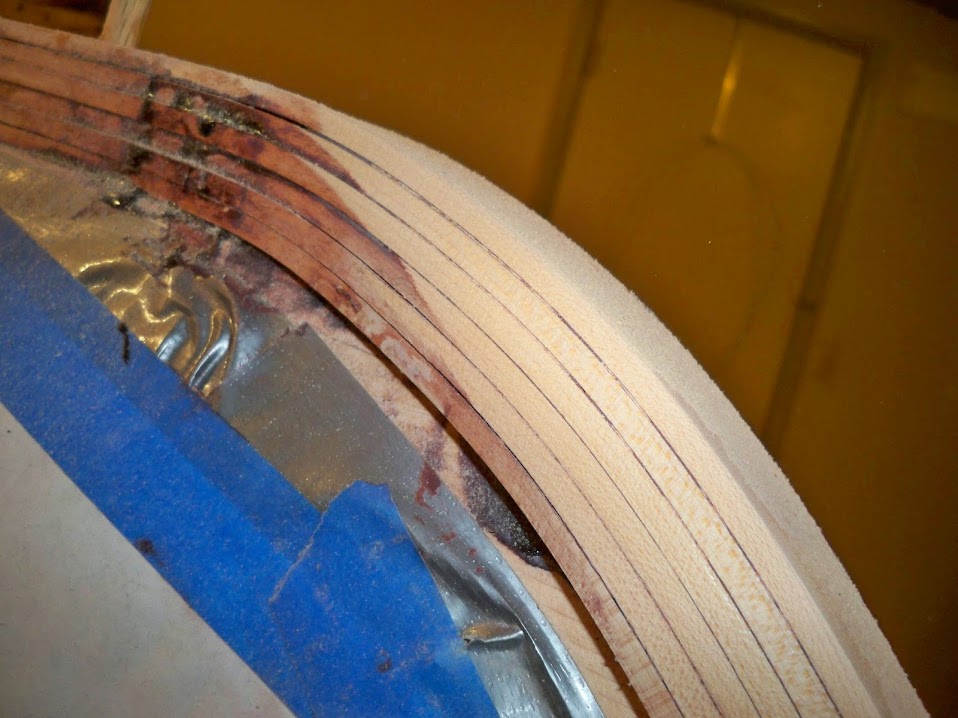

okay I had to make a wood steamer using some PVC pipe for the stem pieces I used a short tube I'll use a larger one for the gunnels.

I heated the wood / hard rock maple 3/16" x 1 1/8" x 40" about an hour after soaking it for 4 hours.

I made a sepreat form for this using my template I made to draw the internal stems; after they cooled I took duct tape and wrapped the ends to hold themthen removed all clamps and then put it right on to the canoe to see mt match.

It needs a slight bit of sandinf where the bend is the tightest.

What I would like is to hear from you guys about gluing these strips together; I've seen where guys are using EPOXY RESIN? to glue these together.

Why not TiteBond or CASCOPHEN?

And I saw some guys mixing in something to the resin like saw dust?

TiteBond is easier to work w/ than CASCOPHEN less mess wipes up w/ water.

BUT IT ALL GETS COVERED W/ GLASS AND EPOXY RESIN?

Little help here to understand please there must be a reason?

I never buy varnish in anything larger than a quart. Seems that I often don't get a good seal on the lids, get distracted and things skim over. Unlike cold country I live in hot humid south. So my building season is different.

Don't get greedy when varnishing. Drips from too much are difficult enough to get out. Don't forget to sand between coats. I hear sanding is fun.

Thanks Grumpy....Still a good wasy away for the varnish.

Well I went ahead and glued the outer stem w/ CASCOPHEN

and only used one screw as a temp hold I'll replace it w/ a dowel and may add some more dowels, we'll see?

Bruce

How does that stem finish out to the bottom of the hull?

You know I can't make up my mind on this? the plans show a Keel strip/ rub strip really 3/4" x 3/4", but they didn't use an outter Stem.

I can make that call once the bottom has been glassed; the only reason I'm against the Keel strip is because I'll have to put screws threw my bottom pattern; unless I use dowels and CASCOPHEN.

Take a look at what I have and tell me what you think you would do.

Thank you for any and all help w/ this build; I'm still learning this is my first boat ever.

Wow - that is coming along really nicely. I like the idea of dowels, although the holes you're putting in the bottom with them are larger than screws.

Look forward to further updates.

Thank you Ars Natura....if I do use dowles it will be done before glassing the inside; Also I'm thinking of running 1 1/2" 6 oz cloth strips of glass down both stdes and the center before glassing w/ two layers of 4 oz DIRECTIONAL glass cloth in an X pattern; I'll run the outside in the X pattern w/ 4 oz Directional cloth as well.

4 layers in all w/ 4 oz cloth and the 1 1/2" strips because of the herringbone pattern

those will cover the seams.

Bruce

Okay I slept on the KEEL idea and decided to go w/ one; this will give added protection to the botton center of the canoe, I add it after glassing the bottom w/ a scarf joint on the keel running up on to the bow & stern stems.

The keel itself will be tapered w/ 10 degree bevels and glued on w/ CASCOPHEN, this glue will adhear to plastics as well as wood.

I'll use screws to glue the strip but remove them after glue has cured and replace them w/ 1/4" oak dowls and CASCOPHEN .

Also I will then run 1 1/2" glass tape down the bottom on each side w/ Epoxy Resin and a strip down the inside covering the dowls befor glassing the inside w/ two layers of 4 oz cloth & resin.

Bruce

Bruce,

the grain on that cedar is really nice. You're going to end up with one hell of a beautiful canoe.

Gero

Thank you Gero...I think I'm going to use every bit of the cedar too, it's very close on having enough and I've wasted very little mostly nots that wouldn't bend w/ out breaking.

I'm fitting the last pieces on the first side now and have started on my decks they are going to take some time; doing a bit of inlay.

Bruce

Okay one end finished bottom closed in; there's still a good bit of filling and sanding.

I wet it down to show how it will look when the resin is applied; and you can see the other side how much is left to fill in.

Well while waiting for glue to dry I started on the bow and aft decks.

And I'll be adding another Native American Symbol; inlaid Walnut into Red Cedar

the gunnels will be Maple.

The canoe's name will be Serenity; I'll be adding that later.

Bruce

Well I had to rip out the rest of the cedar I had left today and run the cove and bead.

Then the inlay was completed; tomorrow back to glueing the rest of the strips.

Check it,

That looks great for a freehand router job. We'll have to start calling you "Steady Eddy".

Gero

Thank you Gero.... Yes you need a steady hand and a sharp bit and pacientes

Bruce

OKAY THE HULL IS CLOSED IN AND THE SECOND STEM IS BENT; NOW TO GLUE ON THE STEM.

THEN LET THE SANDING BEGIN; I MADE ANOTHER PATTERN IN THE BOTTOM THIS TIME IT'S AN ARROW, YOU'LL SEE THIS BETTER WHEN THE GLASS AND EPOXY RESIN GO ON.

I'M HOPPING TO START GLASSING ON SAT.

Bruce

Very nice design. Look forward to seeing it with the first coat of glass/epoxy.

Gero

Thank you Gero...I'm looking forward to seeing that myself; Sanding is well under way and I'm still hoping to get at least the first section of glass cloth down on Sat.

Bruce

OKAY HERE I AM PUTTING THE LAST OF THE 150 GRIT SANDING ON THE HULL ONE MORE GOOD HIT W/ 220 AND IT'S TIME TO START GLASSING.